Fibered Vs Non Fibered Aluminum Roof Coating

Overall we would recommend a fibered product over a non fibered product because the advantages outweigh the cost.

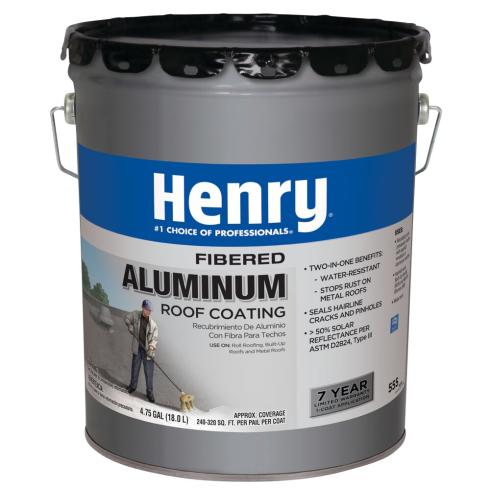

Fibered vs non fibered aluminum roof coating. 5 gallon pails 55 gallon drums karnak 169 non fibered aluminum roof coating is a formulation of selected asphalts refined solvents and fine aluminum flakes. Subpar reflectivity composed of asphalt aluminum paste fillers hydrocarbon solvents and other chemicals aluminum coatings claim to lower roof temperatures and reflect ultraviolet rays. However according to the cool roof rating council an organization that evaluates solar reflectance and thermal emittance these roof coatings are 20. Henry 555 aluminum roof coating is an ultra premium fibered aluminum roof coating that forms a shiny tough reflective surface.

169 non fibered aluminum roof coating available in. Non fibered aluminum coating to an asphalt roof to produce a silver finish that reflects the sun s rays and helps reduce heat transfer and energy costs. It can decrease heating and air conditioning costs and keeps the inside temperature of a building up to 20 f cooler in summer. While a non fibered.

When the coating is applied to the roof the aluminum flakes leaf in over lapping parallel layers forming a reflective metallic shield over the base material. However because it spreads thinner it doesn t give as much protection. As you might guess fibered coatings contain extra fibers whereas non fibered coatings do not. This non fibered coating also helps keep base coatings and membranes from drying out to help prevent premature cracking.

The combination of. This coating is designed for use on the roofs of barns homes garages and mobile homes. Coatings that contain these fibers tend to have lower elasticity meaning that they are limited in how far they can bend an. Henry company fibered aluminum 0 9 gallon aluminum reflective roof coating 7 year limited warranty.

169 non fibered aluminum roof coating available in. The extra fibers in fibered coatings reinforce their strength and also control the viscosity thickness of the liquid. The combination of. Non fibered with roof and foundation coatings it s important to understand the major distinctions between fibered and non fibered coatings.

When the coating is applied to the roof the aluminum flakes leaf in over lapping parallel layers forming a reflective metallic shield over the base material. The only advantage to a non fibered product is that it will spread further on a roof so one wouldn t have to use as much product. When karnak 97 fibered aluminum roof coating is applied to the roof the aluminum flakes leaf to the surface providing a reflective metallic shield over the base of the coating.